About Us

Company Information

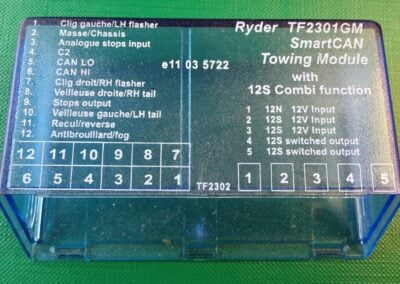

Over the last 70 years, Masona Plastics has manufactured plastic moulded parts to the highest standards whilst remaining competitive. Our customers rate us highly for our technical knowledge as well as our excellent quality and customer service we provide. We manufacture plastic injection moulded components for a wide range of industries, including educational, engineering, electronics, printing, construction and gardening. All of our products and components are manufactured in the UK at our site located in East Sussex. We currently distribute to customers in the UK, as well as the EU and North America.

Over the last 70 years, Masona Plastics has manufactured plastic moulded parts to the highest standards whilst remaining competitive. Our customers rate us highly for our technical knowledge as well as our excellent quality and customer service we provide. We manufacture plastic injection moulded components for a wide range of industries, including educational, engineering, electronics, printing, construction and gardening. All of our products and components are manufactured in the UK at our site located in East Sussex. We currently distribute to customers in the UK, as well as the EU and North America.Design

The initial design and development stage is critical to the success of any project, so why not let us advise you in developing your new product(s)?

The initial design and development stage is critical to the success of any project, so why not let us advise you in developing your new product(s)?

Our in-depth knowledge and years of industry experience have enabled many of our customers to take their ideas from the conceptual stage to reality.

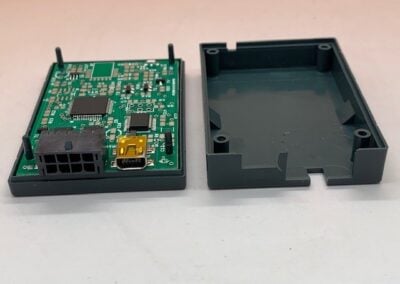

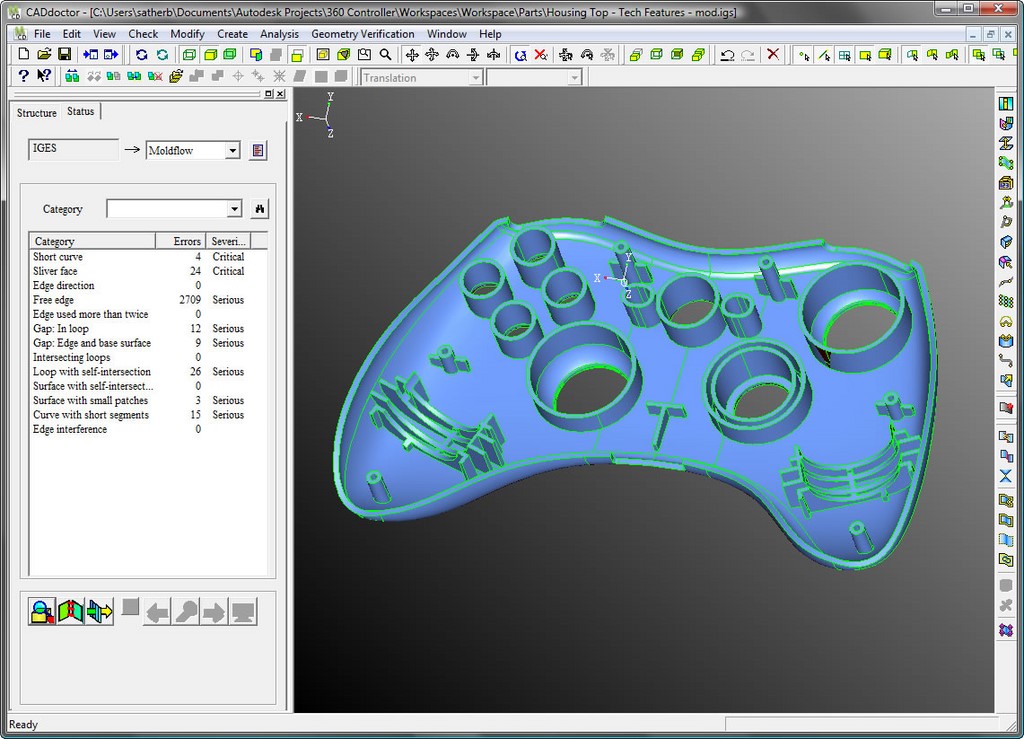

We can develop a project from your simple sketches and produce full 3d CAD models. These CAD models can then be used for further developing or maybe to produce 3D printed parts. Once the design has been finalised the data can be sent to the toolroom for tooling manufacture.

Prototyping

We are also able to offer prototype models and tooling as well as advice on material selection, tooling configuration and specification.

We are also able to offer prototype models and tooling as well as advice on material selection, tooling configuration and specification.

How Does 3D Printing Work?

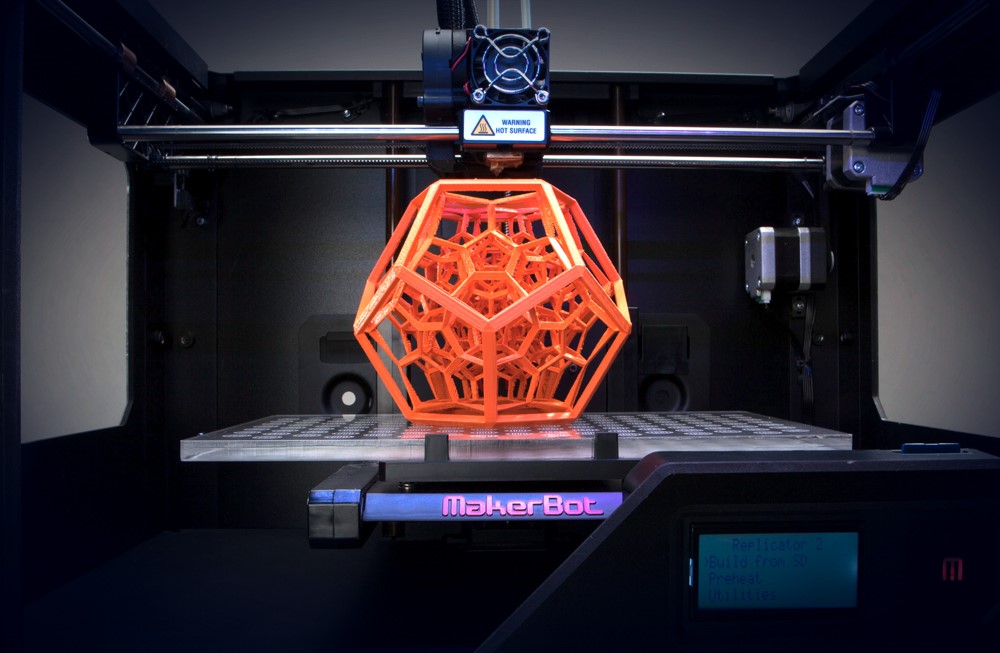

3D printing, commonly known as ‘Additive Manufacture’ is a form of rapid prototyping where models are made layer by layer without the use of moulds.

There are many forms of additive manufacture which all work in slightly different ways, but essentially they all follow the same principals. Each different method has its advantages and drawbacks, whether it be better surface finish, stronger model for working prototypes or full colour models for display models.

What are the basics?

Every 3D printer needs to print from a CAD (Computer Aided Design) file, generally in STL format. This is a digital 3D version of your product that can be created on various different software packages or alternatively existing things can be 3D Scanned (though this is slightly limited).

The printer software then slices this digital model into thousands of wafer thin slices. These slices are then sent to the printer one by one. Material is then laid down in the exact cross sections of the slices, one on top of the other from the bottom to the top until you are left with your lovely new product.

Toolmaking

Injection Moulding

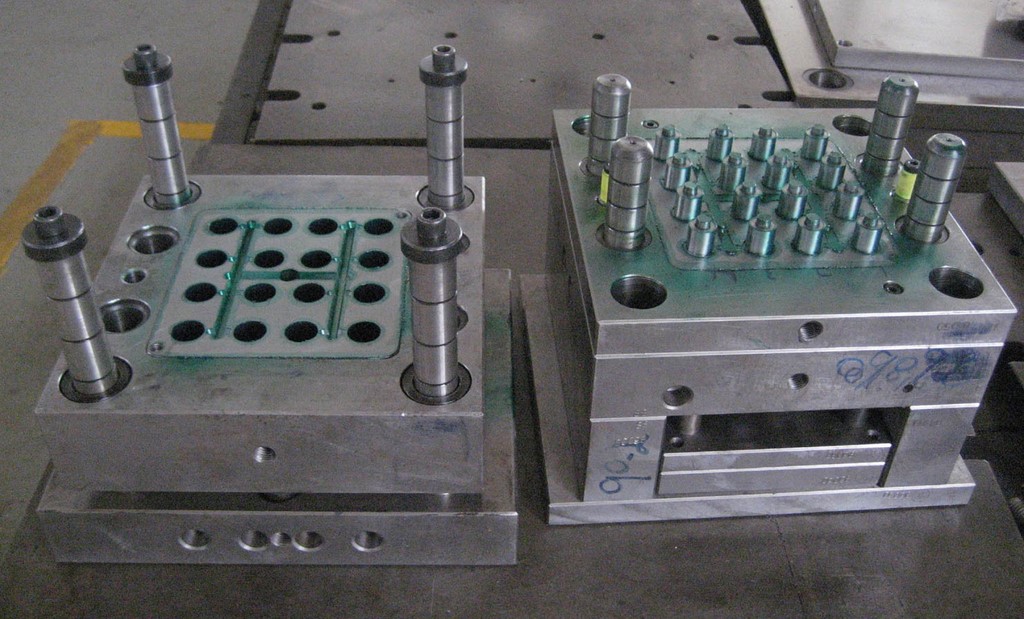

We take great pride in our craftsmanship as well as our service to our customers.

Over the last 3 years Masona Plastics invested over £1 million in NEW injection moulding machines to go into our brand new purpose built factory in the heart of Sussex. This has ensured that Masona is able to offer the best quality and service. The new machinery is up to 80% more efficient than the existing plant making Masona a “greener” option for our customers.

Our capacity now includes 16 injection machines, all fitted with the latest digital servo driven robotics and conveying equipment.

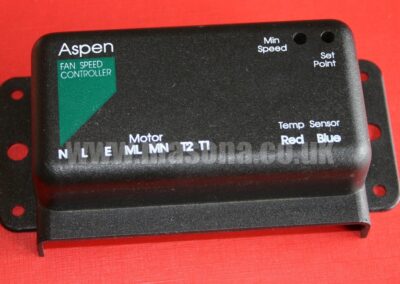

Our mouldings are used in a wide variety of industries that include:

· Educational

· Engineering

· Packaging

· Electronics

· Recreational

We provide cost effective, quality plastic injection mouldings. From the highly complex to the straightforward, components can be moulded in a variety of thermoplastic materials, including ABS, Acetal, Nylon, Polycarbonate and Polypropylene, and where practical the use of reprocessed materials. We are also able to colour these materials if required.

We have an established reputation for tackling difficult projects requiring special technique.